The Importance of Choosing the Right CNC Precision Machining Parts Suppliers

In today's fast-paced industrial landscape, the demand for high-quality precision components is unparalleled. Businesses across various industries rely on specialized suppliers to provide precision machining parts that meet stringent specifications. This article delves into the realm of cnc precision machining parts suppliers, highlighting their significance and the factors to consider when choosing the right partner for your manufacturing needs.

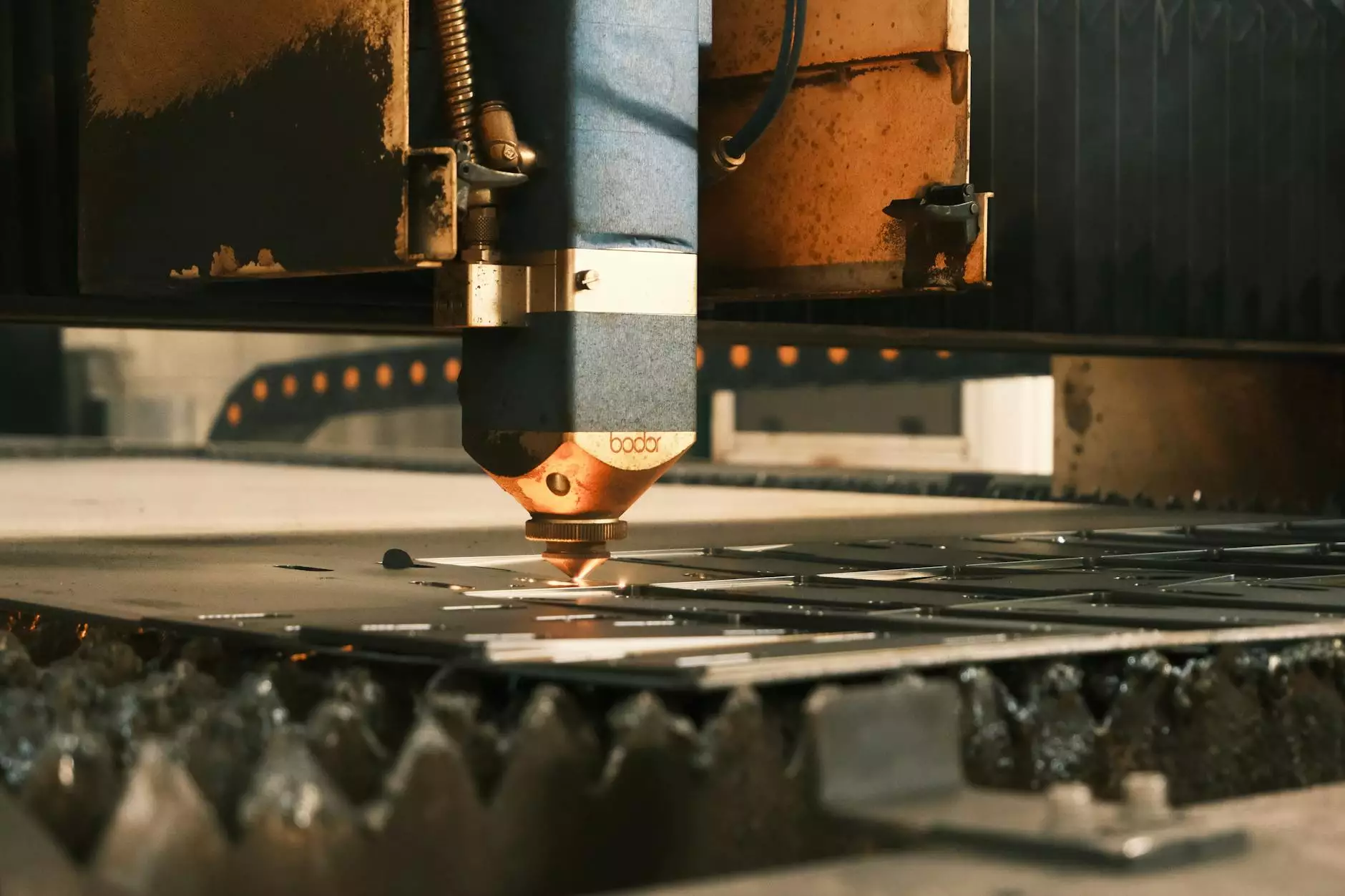

Understanding CNC Precision Machining

CNC, or Computer Numerical Control, machining is a technology that uses computer-controlled machines to create precision parts from various materials. The accuracy and consistency provided by CNC machining make it essential in sectors such as aerospace, automotive, medical devices, and more. The process involves:

- Design: Creating 2D or 3D designs for the parts using CAD software.

- Programming: Converting designs into machine-readable codes.

- Machining: Utilizing CNC machines to cut, shape, and finish materials according to specifications.

- Quality Control: Ensuring that each part meets the required tolerances and quality standards.

Why Partner with Reliable CNC Precision Machining Parts Suppliers?

Partnering with reliable cnc precision machining parts suppliers can significantly impact your business operations. Here are some benefits:

1. High-Quality Products

Reputable suppliers employ advanced technology and quality control measures to ensure that every part is produced to the highest standards. This reliability is crucial for industries where safety and performance are paramount.

2. Cost Efficiency

While it may seem that opting for cheaper suppliers could save money, the long-term costs associated with poor-quality parts can outweigh initial savings. High-end suppliers may offer better pricing structures while ensuring that parts last longer and function better, reducing operational disruptions.

3. Expertise and Support

Leading cnc precision machining parts suppliers have extensive knowledge of machining processes and materials. Their expertise can help businesses select the right materials and manufacturing techniques, optimizing the final product's efficiency and effectiveness.

4. Customization Capabilities

The best suppliers provide options for customization, allowing clients to obtain parts tailored to specific requirements, from small adjustments to complex designs. This flexibility can be a game-changer in meeting unique manufacturing needs.

Key Factors to Consider When Selecting CNC Precision Machining Parts Suppliers

When searching for the right supplier, consider the following crucial factors:

1. Experience and Reputation

Look for suppliers with a proven track record in the industry. A supplier's reputation can indicate their reliability and the quality of their products. Reading reviews and client testimonials can provide insight into their performance.

2. Certifications and Standards

Check if the supplier adheres to international standards such as ISO 9001 or AS9100, which denote quality management systems. Such certifications reflect their commitment to quality and continuous improvement.

3. Production Capabilities

Evaluate the supplier’s machinery and technology to ensure they can handle your specific requirements. Advanced CNC machines and technologies such as 5-axis machining can enhance precision and efficiency.

4. Material Options

Different projects require different materials. Ensure the supplier can work with a variety of materials, including metals, plastics, and composites. This flexibility can be crucial for specialized projects.

5. Communication and Customer Service

Effective communication is key to a successful partnership. Choose suppliers who are responsive and willing to work closely with you throughout the production process.

Leading CNC Precision Machining Parts Suppliers: A Closer Look

Among the various suppliers in the industry, Deep Mould (found at deepmould.net) is recognized for its commitment to quality and customer service. Below are some features that set them apart:

1. State-of-the-Art Technology

Deep Mould utilizes the latest CNC technologies, ensuring that their machining processes remain at the forefront of the industry. This investment in technology not only enhances precision but also increases efficiency, allowing for quicker turnaround times on orders.

2. Comprehensive Service Portfolio

From prototyping to mass production, Deep Mould offers a complete range of services. This capability makes it easier for businesses to manage their manufacturing processes through a single, reliable supplier.

3. Expertise Across Industries

Deep Mould serves various sectors, including automotive, aerospace, medical, and electronics, demonstrating their versatility and understanding of different industry requirements.

4. Commitment to Sustainability

Deep Mould is also dedicated to sustainable practices. They strive to minimize waste and reduce their environmental impact, aligning with the growing trend of sustainability in manufacturing.

The Future of CNC Precision Machining

The future of CNC precision machining looks bright as technology continues to advance. Innovations such as integrated AI systems for predictive maintenance and smarter manufacturing processes will enhance the capabilities of precision machining. Suppliers who adopt these innovations will lead the industry, providing unmatched quality and efficiency.

Conclusion

Choosing the right cnc precision machining parts suppliers is vital for your business's success. The quality of parts directly impacts the performance, reliability, and safety of your final products. By considering aspects such as experience, production capabilities, and customer service, you can ensure that your manufacturing needs are met with the utmost precision and efficiency.

In the competitive manufacturing landscape, partnering with a reliable supplier like Deep Mould can give you a significant edge. Their commitment to quality, technology, and customer satisfaction makes them an excellent choice for businesses looking to thrive in today's market.