The Importance of Barcode Labels and Ribbons in Modern Business

In today’s fast-paced business environment, effective inventory management and streamlined operations are crucial for success. One key element that plays a vital role in achieving these objectives is the use of barcode labels and ribbons. This article delves into the specifics of these tools, their benefits, and how they can transform your business operations.

Understanding Barcode Labels

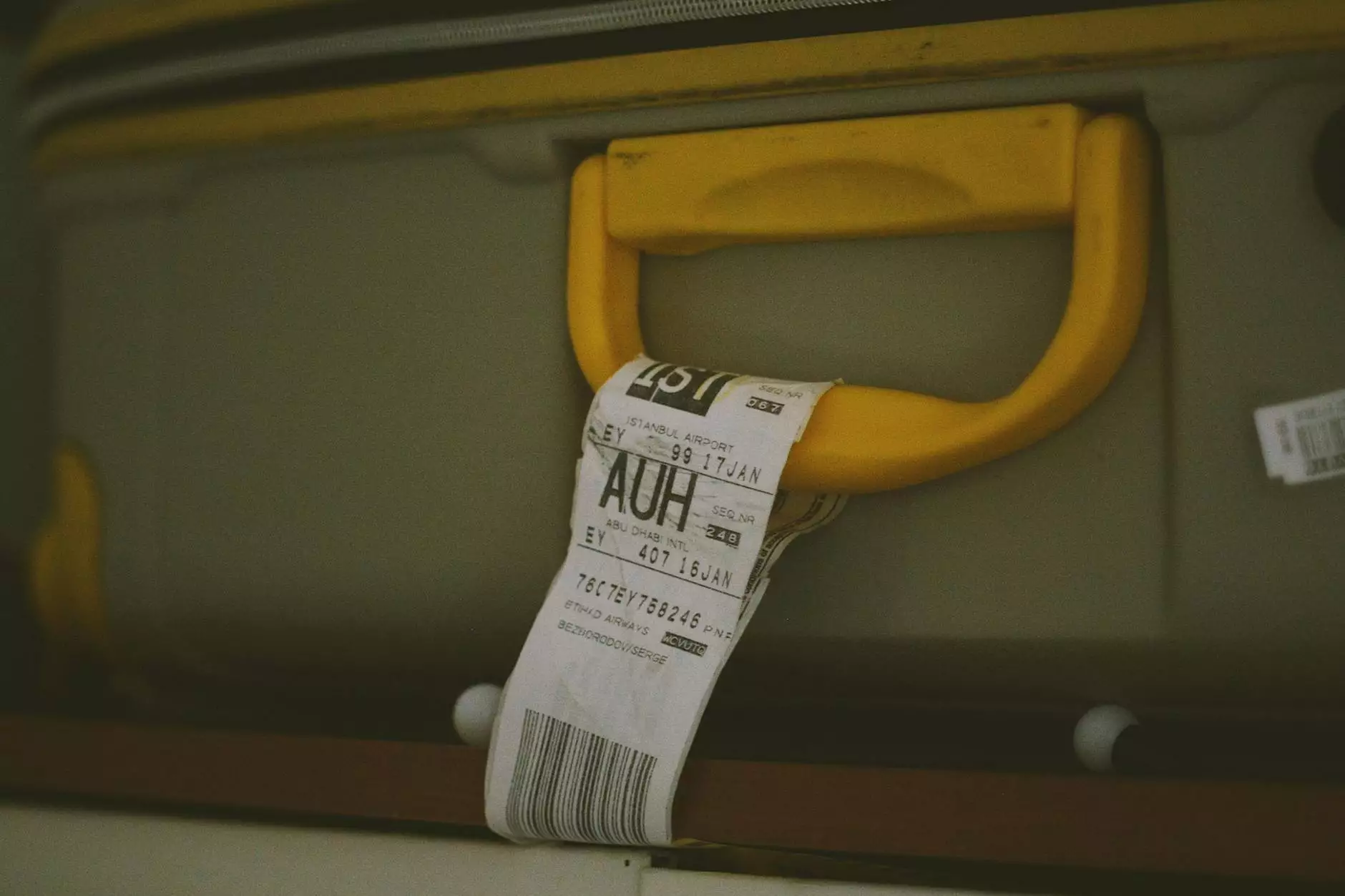

Barcode labels are machine-readable representations of data that allow for quick identification of products, resources, and assets. These labels consist of a series of parallel lines, or bars, that encode information about a product, such as its price, stock number, and additional details. The data encoded in a barcode can be accessed through special devices like barcode scanners or smartphones equipped with camera functionality.

Types of Barcode Labels

- Paper Labels: Cost-effective and versatile, ideal for short-term use.

- Polyester Labels: Durable and weather-resistant, designed for long-term applications.

- Vinyl Labels: Flexible and resistant to moisture, perfect for outdoor use.

- Specialty Labels: Customizable for unique applications, including RFID integration.

The Role of Ribbons in Printing

Ribbons are an essential component of thermal transfer printing, which is one of the most common methods for creating barcode labels. The ribbons transfer ink onto the label material, creating legible barcodes that can withstand various environmental conditions.

Types of Printing Ribbons

- Wax Ribbons: Ideal for paper labels with moderate durability requirements.

- Resin Ribbons: Best for plastic labels needing resistance to chemicals and heat.

- Wax-Resin Ribbons: A versatile option that provides the best of both worlds—price and durability.

Benefits of Using Barcode Labels and Ribbons

Integrating barcode labels and ribbons into your business operations can yield numerous benefits:

1. Improved Accuracy

One of the most significant advantages of barcode technology is enhanced accuracy. By eliminating human error associated with manual data entry, businesses can achieve higher levels of precision in inventory management, order fulfillment, and sales tracking.

2. Increased Efficiency

Barcode scanning is a quick and efficient method of data collection. This technology significantly accelerates processes like receiving, shipping, and inventory checks, allowing employees to focus on more critical tasks, thus improving overall productivity.

3. Enhanced Inventory Management

The use of barcode labels provides businesses with the ability to monitor inventory levels in real time. Automated updates from scans ensure that stock levels are always accurate, reducing the risk of overstocking or stockouts.

4. Cost Savings

While there is an initial investment in barcode printing systems, the long-term savings generated from improved efficiency and accuracy make it a worthwhile expense. Businesses can expect reduced labor costs, lower inventory holding costs, and fewer mistakes, which translate into significant savings over time.

5. Greater Customer Satisfaction

Fast and accurate order processing leads to improved customer satisfaction. With the ability to track orders and monitor delivery times, businesses can provide better service to their clients, fostering loyalty and repeat business.

Implementation of Barcode Labels and Ribbons in Your Business

To successfully implement barcode labels and ribbons in your organization, consider the following steps:

1. Assess Your Needs

Begin by evaluating the specific requirements of your business. What types of products or assets will you be labeling? Understanding your needs will guide you in selecting the appropriate barcode labels and ribbons.

2. Choose the Right Barcode System

Select a barcode system that best suits your operations. There are different types of barcodes, including UPC, QR codes, and Code 128. Your choice will depend on how you plan to use the barcodes and what information needs to be conveyed.

3. Invest in the Right Equipment

Purchase quality printers that can handle barcode labels and ribbons. Look for models that support various label materials and sizes to meet your diverse needs. Don’t forget to invest in scanners that can accurately read barcodes quickly and efficiently.

4. Train Your Team

Proper training is essential for effective implementation. Ensure that your team understands how to use the barcode system, from printing labels to scanning items efficiently. This will maximize the efficiency of the new system.

5. Monitor and Improve

After implementation, continuously monitor the performance of your barcode system. Gather feedback from employees and make adjustments as needed to optimize operations.

Conclusion

In conclusion, the integration of barcode labels and ribbons is not just an optional enhancement but a crucial element for modern businesses aiming for efficiency and accuracy. By utilizing these tools, companies can improve their inventory management, reduce costs, and increase customer satisfaction. As the business landscape continues to evolve, investing in barcode technology from reputable suppliers like Omega Brand can help pave the way for future success.

If you’re looking for quality printing services, electronics, and computers, visit Omega Brand to explore our offerings and discover how we can assist you in implementing an efficient barcode solution tailored to your needs.