Transforming Your Ideas: The Role of a Rapid Prototyping Company

In today’s fast-paced business environment, the demand for innovation is more significant than ever. Companies are continuously seeking ways to accelerate product development, enhance design quality, and reduce time-to-market. This is where a rapid prototyping company comes into play, offering state-of-the-art solutions to turn concepts into tangible products quickly and efficiently.

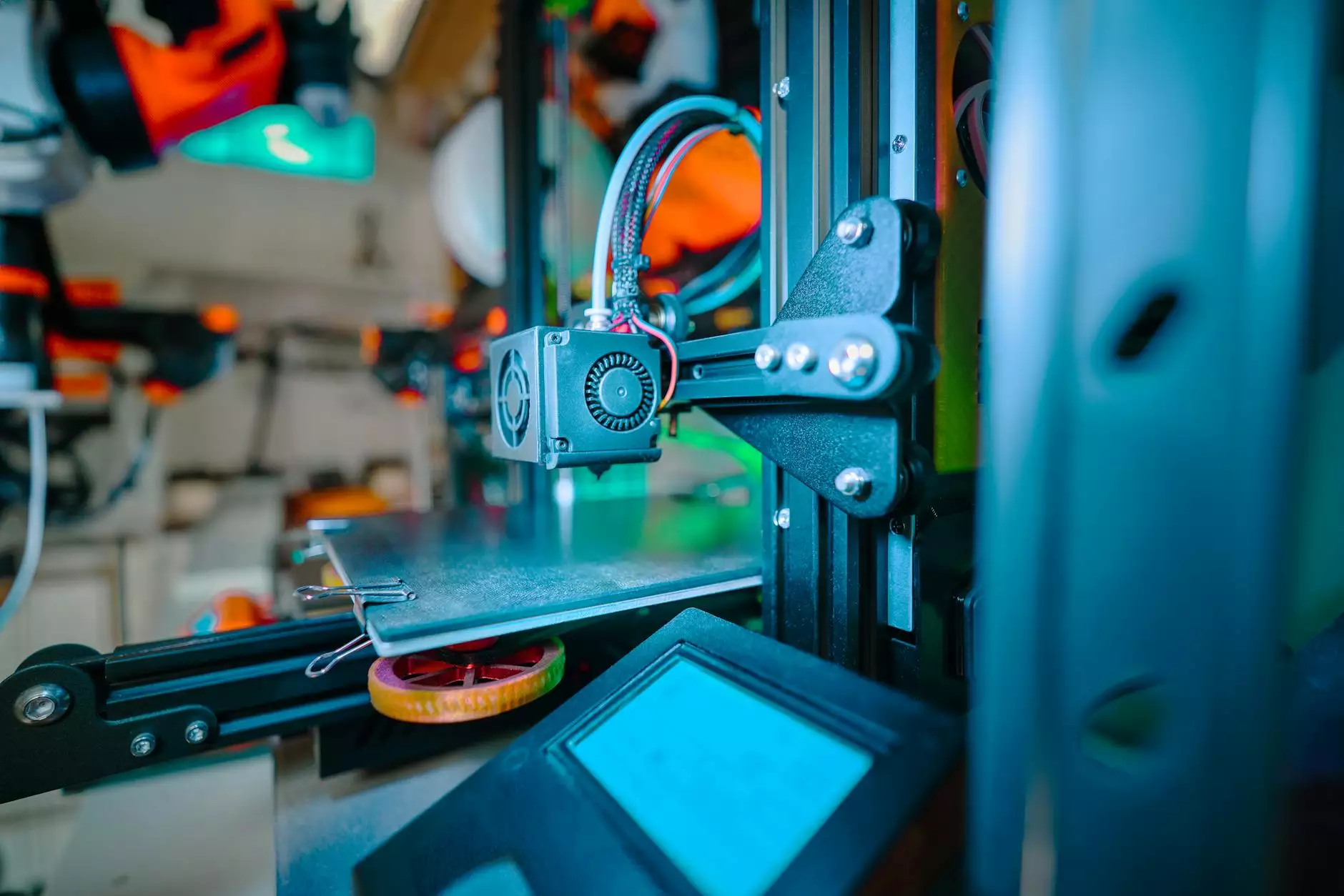

Understanding Rapid Prototyping

Rapid prototyping refers to the process of quickly creating a scale model or prototype of a physical part or assembly using 3D computer-aided design (CAD) data. The primary goal is to visualize and test the design before moving into full-scale production. This method significantly reduces the risks associated with product development by allowing for immediate feedback and iterative design improvements.

Key Benefits of Working with a Rapid Prototyping Company

The advantages of utilizing a rapid prototyping company are numerous and can significantly impact your business operations:

- Speed: Rapid prototyping companies can produce prototypes in days, allowing for quick testing and refinement.

- Cost-Effectiveness: By identifying design flaws early, businesses can save on the costs associated with later-stage production issues.

- Improved Design Validation: Prototyping enables real-world testing, providing valuable feedback that can be incorporated into the final product.

- Enhanced Collaboration: Prototypes serve as tangible communication tools that enhance collaboration among team members and stakeholders.

Industries Benefiting from Rapid Prototyping

Rapid prototyping can be applied across various industries, including:

- Automotive: Designing and testing new parts for vehicles to improve safety and performance.

- Aerospace: Creating lightweight components that meet stringent safety standards while enhancing efficiency.

- Consumer Electronics: Rapidly iterating on designs to meet the fast-paced demands of the market.

- Medical Devices: Developing prototypes of surgical instruments and implants that are crucial for patient safety and compliance.

How Rapid Prototyping Enhances Metal Fabrication

As a leading rapid prototyping company, DeepMould recognizes the necessary integration of metal fabrication techniques. This hybrid approach allows for the creation of functional prototypes that reflect the final product's design and operational characteristics. Metal fabrication enhances the robustness and performance of prototypes, particularly for applications where durability is essential.

Advanced Techniques in Metal Fabrication

Modern rapid prototyping companies utilize various advanced methods in metal fabrication, including:

- 3D Metal Printing: This technology uses laser sintering to fuse metal powders layer by layer, creating complex geometries that traditional fabrication methods struggle to achieve.

- CNC Machining: Precision milling and turning processes that deliver high accuracy and repeatability for critical components.

- Sheet Metal Fabrication: Cutting, bending, and shaping metal sheets to create unique designs and prototypes.

Choosing the Right Rapid Prototyping Company

When selecting a rapid prototyping company, several factors are vital to ensure you partner with a capable and reliable provider:

- Experience: Look for companies with a proven track record in your industry.

- Technology: Ensure they utilize the latest technologies and methods to produce high-quality prototypes.

- Custom Solutions: A good prototyping partner should offer tailored solutions that meet your specific needs.

- Client Testimonials: Review feedback from previous clients to gauge satisfaction and reliability.

The Process of Rapid Prototyping: From Concept to Creation

The rapid prototyping process typically involves several key stages:

1. Initial Consultation

During this phase, clients discuss their ideas with the prototyping company to identify requirements and objectives.

2. Design Development

The company will develop a 3D CAD model based on the client's specifications, ensuring that all design considerations are accounted for.

3. Prototype Production

Once the design is finalized, the company will produce the prototype using the selected fabrication methods.

4. Testing and Evaluation

The prototype undergoes rigorous testing to evaluate its performance, functionality, and adherence to specifications.

5. Revisions and Finalization

Feedback is incorporated, and revisions are made to enhance the design before moving to production-ready standards.

The Future of Rapid Prototyping

The landscape of rapid prototyping is ever-evolving. Technological advancements such as artificial intelligence and machine learning are beginning to play a role in speeding up design processes and improving accuracy. Additionally, ongoing innovations in materials science are expanding the range of suitable materials for prototyping, further enhancing resilience and functionality.

Success Stories: How Companies Transformed with Rapid Prototyping

Many organizations have successfully leveraged the capabilities of a rapid prototyping company. For instance:

Case Study: Automotive Innovation

An automotive manufacturer needed a complex part that was critical to the performance of a new model. By engaging a rapid prototyping firm, they developed a lightweight yet durable prototype that underwent extensive testing in just weeks. The prototype’s success led to a 30% reduction in production costs and improved the vehicle's performance.

Case Study: Medical Device Development

A healthcare company sought to create a new surgical tool. Utilizing rapid prototyping, they produced several iterations of the tool, allowing for real-time feedback from surgeons. This facilitated essential design improvements, significantly increasing the final product's usability and safety.

Conclusion: Embrace the Future with a Rapid Prototyping Company

In conclusion, partnering with a rapid prototyping company like DeepMould not only accelerates your product development cycle but also enhances your overall design quality and innovation capabilities. By integrating advanced metal fabrication techniques and utilizing cutting-edge technologies, you can transform your ideas into reality faster and more efficiently than ever before. Don’t let your concepts remain on paper; take the leap and embrace the future of prototyping today!